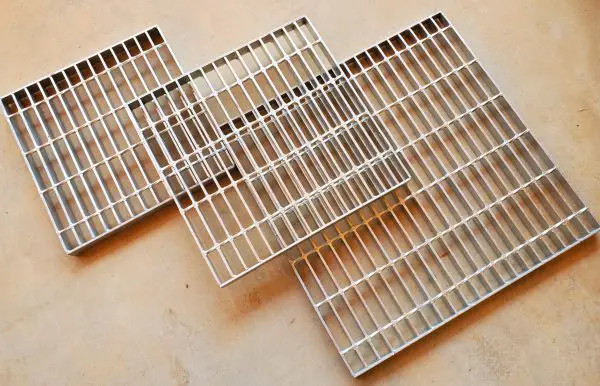

Galvanized Steel Pit Covers

Our hot-dipped galvanized steel pit covers are well-suited for use in both residential and industrial applications. Galvanized steel is a great choice for when your project needs a strong and durable material.

Galvanizing is also the better choice over non-galvanized steel pit covers, due to the fact that the galvanized coating helps protect the steel from corrosion. It does this by not allowing moisture and corrosive chlorides and sulfides to attack the steel. Additionally, we offer this product in a wide variety of sizes that are light, heavy, and extra heavy–duty. Additional sizes may be available upon request.

NEED TO PURCHASE A LARGE QUANTITY? CALL OR EMAIL US FOR DISCOUNTED PRICING!

The Benefits of Using Galvanized Steel for Pit Covers

Galvanized steel pit covers can endure significant wear and tear due to the robust nature of the galvanization process. This process involves submerging the steel sheet in molten zinc, resulting in a protective coating that is incredibly tough. The zinc coating creates a protective buffer against physical impacts, making pit covers highly resistant to physical damage. As a result, galvanized steel is a preferred choice for industrial steel applications where pit covers are regularly exposed to extreme conditions.

The inherent rust resistance of galvanized steel pit covers stems from the zinc coating applied during the hot dip galvanizing process. When steel is submerged in hot dip molten zinc, a metallurgical reaction occurs that forms layers of zinc-iron alloy and a pure zinc coating on the surface. Zinc acts as a sacrificial anode, meaning it will corrode in place of the steel, thus offering corrosion protection.

Plus, the formation of zinc oxide on the surface when exposed to the atmosphere provides an additional layer of protection against corrosion. This process ensures that pit covers made with galvanized steel are resistant to rust — even when completely exposed to environmental conditions that accelerate the corrosion process.

Galvanized steel pit covers are remarkably easy to inspect during the maintenance process. The hot dip process ensures that the zinc coatings are uniform, covering every surface and edge with a consistent layer that can be visually inspected for signs of wear or damage.

Unlike other protective coatings that might require specialized equipment to assess their integrity, the condition of galvanized metal can be evaluated with a simple visual inspection. Any damaged steel sections or areas where the zinc has been compromised are readily apparent. This allows for targeted maintenance that ensures the integrity of the pit cover remains intact. Easy inspection reduces downtime and ensures that any necessary repairs can be addressed promptly.

The long lifespan of galvanized steel pit covers is thanks to the combined effects of the galvanization process and the protective qualities of zinc. The hot dip galvanized steel undergoes a transformation that not only provides immediate protection against environmental factors but also continues to safeguard the metal over time. In addition, the surrounding zinc coating acts as a barrier against moisture and pollutants that would otherwise lead to the rapid deterioration of the steel.

Moreover, this steel exhibits enhanced durability and resistance to mechanical wear, contributing to a longer life expectancy. This durability — coupled with the minimal maintenance required and the ability to withstand harsh conditions — ensures that galvanized steel pit covers remain functional and effective for years.

In Addition, We Also Offer

If You’re Interested in Galvanized Steel Pit Covers, Reach Out Today

When you need pit covers that can endure ambient humidity, severe water exposure, and intense conditions, you can always place your trust in galvanized steel. Reach out to The Trench Grate Store for additional information on our galvanized steel pit covers and to order one for your facility or other needs.